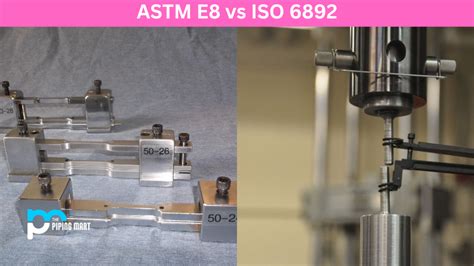

torsion test specimen similar to astm standard e8|astm e8 tensile testing : importing ASTM E8 specifies the exact testing conditions, including loading rate, load cell accuracy, and extensometer requirement. Meanwhile, ISO 6892 has broader tolerances, allowing for load application, gauge length, and strain . VIA41. PUBLICIDADE. Fone/Whatsapp: (73) 3281-9083 / 73 98213-8727 - E-mail:

[email protected] Todos os direitos reservados ao VIA 41.

{plog:ftitle_list}

WEBPlay 300 Shields Extreme casino slot game online for your chance to win real money. Free game demo available. Safe, regulated, and secure. ×. Need help? Visit the Help Centre . 1-877-252-3287 Email Us . 300 Shields Extreme. Game Summary. Bet: $0.25 - $10.00 Number of Paylines: 25

ODM Impact Testing

difference between astm e8 m

The ASTM E8 / ASTM E8M standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break .What is the ASTM standard for torsion test? Various ASTM standards cover torsion testing, such as ASTM A938 for wire and ASTM E2207 for thin-walled tubular specimens. Why is torsional analysis important? ASTM E8 specifies the exact testing conditions, including loading rate, load cell accuracy, and extensometer requirement. Meanwhile, ISO 6892 has broader tolerances, allowing for load application, gauge length, and strain .

astm e8 tolerance

ISO 6892-1 is similar but not equivalent to ASTM E8/E8M. This guide is designed to introduce you to the basic elements of an ISO 6892-1 tensile test and will provide an overview of the .

1.2 The gauge lengths for most round specimens are re-quired to be 4D for E8 and 5D for E8M. The gauge length is the most significant difference between E8 and E8M test specimens. . The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from .

ASTM E143: This standard provides guidelines for conducting torsion testing of metallic materials. It covers both static and dynamic testing methods and specifies the . ASTM E8M-22 is similar to E8. As per the E8 test method, the gauge length required is 4D whereas it is 5D for E8M-22. Both procedures cover the tension testing of metallic materials and help determine tensile properties .

ASTM E8 / E8M allows for many different specimen types and defines suitable geometries and dimensions for each one. Bars, tubes, sheets, pin-loaded specimens, round specimens, and powdered metallurgy products are some of .The gage length is the most significant difference between E8 and E8M Test Specimens Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by . The gage length is the most significant difference between E 8 and E 8M Test Specimens Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area and density.ASTM E8 Tensile tests provide information on the strength and ductility of materials under uniaxial tensile stresses. From fragile wires to structural steel, from lead and copper to aluminum, steel and titanium alloys, metal alloy .

I'm working on material torsion strength, so I have to do the test of torsion specimen test according to ASTM standard if anybody knows the same please reply me Mechanical Characterization Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability . The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area and density.1.2 The gauge lengths for most round specimens are re-quired to be 4D for E8 and 5D for E8M. The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a

1.2 The gauge lengths for most round specimens are re-quired to be 4D for E8 and 5D for E8M. The gauge length is the most signiÞcant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to aThe ASTM E8 standards provide a comprehensive set of test methods that play a pivotal role in understanding the mechanical behavior of metallic materials. The primary emphasis is on tension testing, conducted under the standard conditions of room temperature.1.2 The gauge lengths for most round specimens are re-quired to be 4D for E8 and 5D for E8M. The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a1.2 The gauge lengths for most round specimens are re-quired to be 4D for E8 and 5D for E8M. The gauge length is the most signiÞcant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a

While the standard provides typical test speed ranges, it is important to be aware of the isothermal properties of the material. ASTM A938 explicitly states that it is critical to monitor the temperature of the wire while under test. If the testing increases the temperature above a specific threshold, the test speed should be lowered.

The approach adopted to this end is finite element analysis that is carefully verified. Stress concentration factors are thus accurately determined to three figures for all of the various types of standard round specimens in ASTM E8/E8M-16a, Standard Test Methods for Tension Testing of Metallic Materials.approved in 1924. Last previous edition appproved 2000 as E8–01e2. 2 Annual Book of ASTM Standards, Vol 01.02. 3 Annual Book of ASTM Standards, Vol 01.03. 4 Annual Book of ASTM Standards, Vol 02.02. 5 Annual Book of ASTM Standards, Vol 03.01. 6 Annual Book of ASTM Standards, Vol 14.02. 1 *A Summary of Changes section appears at the end of .

Kedua specimen shape dan specimen machining prosesnya menentukan ASTM E8 test standard. Spesimen harus disiapkan sedemikian rupa sehingga sifat material tidak terpengaruh. Semua area yang mengalami pengerasan regangan melalui pemotongan atau pelubangan selama proses pemesinan spesimen harus diproses sesuai, jika berpengaruh pada properti . SAE 4340 Fracture Toughness Evaluation Following Wang’s Formulation for Spiral Notch Torsion Test Specimens. . that follows ASTM E399-20, Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness K IC of Metallic Materials. The fracture surfaces observed in SNTT and C(T) specimens showed similar fractographies and mechanisms. . The gage length is the most significant difference between E8 and E8M Test Specimens Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area and density. . No comments were found for ASTM E8 / E8M - 11 Standard .1.2 The gauge lengths for most round specimens are required to be 4D for E8 and 5D for E8M.The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy .

The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area and density.1.2 The gauge lengths for most round specimens are required to be 4D for E8 and 5D for E8M.The gauge length is the most significant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area .

astm e8 testing speed

For ASTM A938, the recommended test length (distance between clamping heads) is 8 in. (203 mm). Result: The test specimen is judged to have passed the test if the number of turns is satisfactory. Conclusion: The standard test method, Torsion Testing of Wire ASTM A938, is a valuable technique for measuring wire ductility under torsional loading.

astm e8 tensile testing

Note 2-Gage lengths in these test methods are required to be 4D for most round specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a specific projected area and density.Designation: E8/E8M − 16a´1 E8/E8M − 21 American Association State Highway and Transportation Officials Standard AASHTO No.: T68 An American National Standard Standard Test Methods for Tension Testing of Metallic Materials1 This standard is issued under the fixed designation E8/E8M; the number immediately following the designation indicates the year ofStandard Test Methods for Tension Testing of Metallic Materials Learn about the GrabCAD Platform . Similar models. View Files. Files (4) ASTM E8 Tensile Sample ASTM E8 Tensile Sample / Loading . E8_Render.png. png. January 17th, 2023 ASTM_E8_Subsize_Specimen_Thickness_3mm.STL. stl. January 17th, 2023 .

The gage length is the most significant difference between E8 and E8M Test Specimens Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a .

import Impact Testing

1.2 The gauge lengths for most round specimens are re-quired to be 4D for E8 and 5D for E8M. The gauge length is the most signiÞcant difference between E8 and E8M test specimens. Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material to a1.2 The gauge lengths for most round specimens are required to be 4D for E8 and 5D for E8M. The gauge length is the most . 2.1 ASTM Standards:2 1 These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and are the direct responsibility of Subcommittee E28.04 on Uniaxial1.2 The gage lengths for most round specimens are required to be 4D for E8 and 5D for E8M. The gage length is the most significant difference between E8 and E8M Test Specimens Test specimens made from powder metallurgy (P/M) materials are . 2.1 ASTM Standards:2 A356/A356M Specification for Steel Castings, Carbon, Low Alloy, and Stainless .

export Impact Testing

Resultado da Sensacional hoje tem o Resultado da Lotofácil 2630, veja os números sorteados e quantos ganhadores vão levar prêmio hoje, veja se você ganhou na Lotofácil com os seus números apostados. Sorteio de hoje tem prêmio vai pagar ao ganhador o valor de R$ 1.500.000,00 veja as dezenas sorteadas .

torsion test specimen similar to astm standard e8|astm e8 tensile testing